| PHYSICAL PROPERTY | TEST STANDARD | VALUES |

|---|---|---|

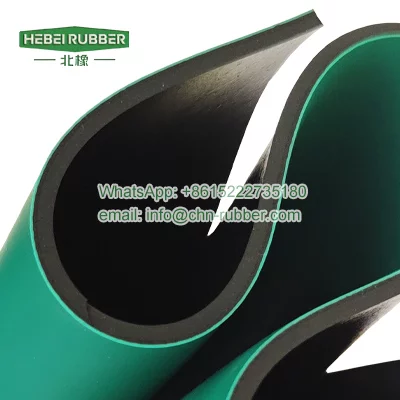

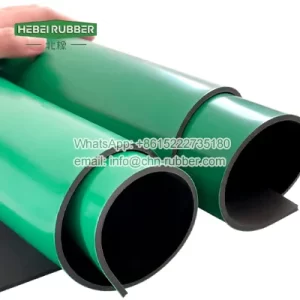

| Thickness | 2mm-100mm | |

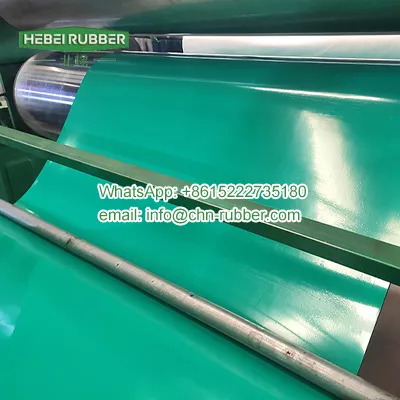

| Width | 1m-2m | |

| Length | 5m/10m/15m/20m | |

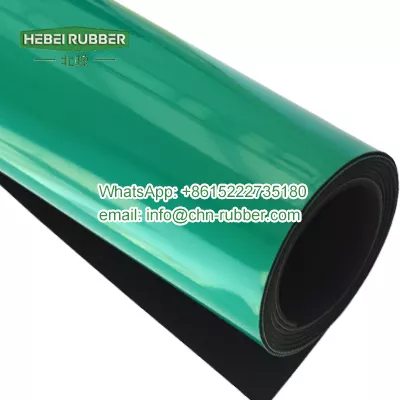

| Color | Green | |

| Gravity | ASTM D397 | 1.5+/-0.5 |

| Hardness | ASTM D2240 | 65+/-5Shore A |

| Tensile Strength | ASTM D412 | 3Mpa |

| Elongation | ASTM D412 | 200% |

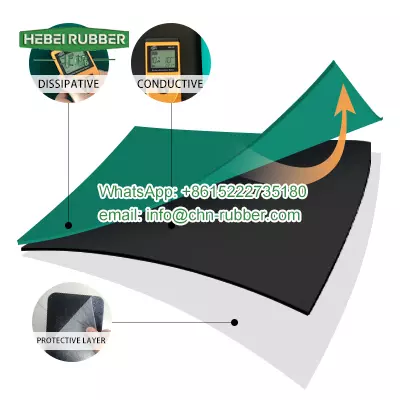

| Top Cover | 10^7 ~ 10^9Ω | |

| Back Cover | 10^3 ~ 10^5Ω |

Static discharge mats are designed to prevent the buildup of static electricity, providing essential protection for delicate electronics and ensuring a safe working environment. Whether used in a manufacturing facility, a repair station, or a laboratory, these mats play a critical role in maintaining the integrity of sensitive components.

Key Features:

- Static Control: The static electricity mat is surface and grounding layer work together to neutralize static charges, reducing the risk of electrostatic discharge.

- Durable and Long-Lasting: Made from high-quality materials, these mats can handle daily wear and resist degradation over time.

- Non-Slip Surface: A slightly textured finish ensures tools and components stay secure during assembly or repair tasks.

- Wide Compatibility: Available in multiple sizes and thicknesses, the mats are adaptable for use on benches, floors, or any static-prone surface.

- Easy Maintenance: static electricity mat designed for practicality, they can be cleaned and maintained without losing their static-dissipative properties.

Versatile - Applications: Resistant to mild heat and chemicals, they are suitable for tasks like soldering or handling specialized materials.

Applications:

- Electronics Assembly: Protect sensitive circuit boards during production or inspection.

- Workstation Safety: Ideal for creating a static-safe zone in repair shops or testing facilities.

Industrial - Environments: Essential for maintaining compliance in ESD-sensitive production areas.

-137x56.png)