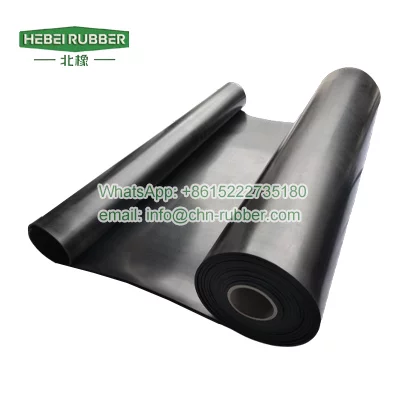

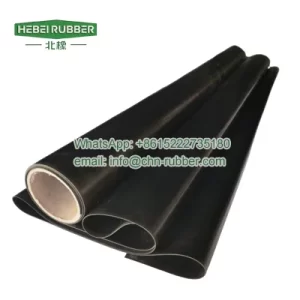

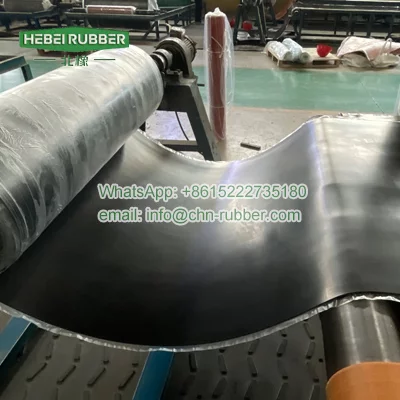

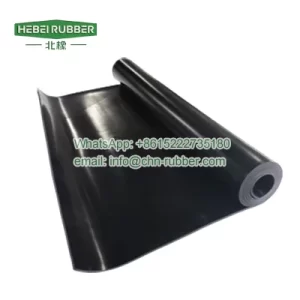

50% EPDM rubber roll performance parameters

| Physical Property | Standard | Parameters |

|---|---|---|

| Gravity | ASTM D397 | 1.4G/CM ³ |

| Hardness | ASTM D2240 | 60+/-5Shore A |

| T.S | ASTM D412 | 7-8Mpa |

| Elongation | ASTM D412 | 350% |

| Working temperature | / | -40℃ ~ +150℃ |

EPDM rubber roll is engineered with enhanced EPDM ozone resistance, ensuring optimal protection against ozone, UV exposure, and weathering. Ideal for both outdoor and industrial environments, this rubber roll maintains flexibility and durability under harsh conditions, offering a reliable solution for sealing, gaskets, and insulation applications.

Key Features:

EPDM Ozone Resistance: Specifically formulated to resist the damaging effects of ozone, extending the lifespan of your materials.

Durable Construction: Offers excellent protection against UV rays, weathering, and extreme temperatures, ensuring long-lasting performance.

Material Composition: Made from high-quality EPDM (Ethylene Propylene Diene Monomer) rubber, known for its strength and resilience.

Flexibility: Maintains flexibility and elasticity even under harsh environmental conditions.

Versatile Use: Available in rolls, suitable for various industrial and commercial applications, including sealing and insulation.

Benefits:

Ozone Protection: EPDM’s inherent resistance to ozone and UV rays ensures that your rubber components stay intact without cracking or degrading.

Long-Term Durability: Perfect for long-term applications in industries such as automotive, construction, and manufacturing.

Cost-Effective: Reduced need for frequent replacements thanks to EPDM’s superior weather and ozone resistance.

Applications:

The EPDM Rubber Roll with ozone resistance is widely used in:

Seals and gaskets for outdoor machinery.

Weatherstripping for windows and doors.

Automotive applications, such as weather seals and under-hood components.

Insulation for piping and HVAC systems.

-137x56.png)