Rubber wear lining performance

| PHYSICAL PROPERTY | TEST STANDARD | VALUES |

|---|---|---|

| Hardness | ASTM D2240 | A36+/-3Shore A |

| Specific Gravity | ASTM D397 | 0.96+/-0.03 |

| Modulus@500% | ASTM D412 | 2.1 |

| Tensile Strength | ASTM D412 | 23Min |

| Elongation | ASTM D412 | 800% |

| Resilience | / | 80% |

| Tear Strenth | ASTM D624 | 40Min |

| Wet Abrasion | ASTM D5963 | 103% |

| Working Temperature | / | -40℃ ~ +80℃ |

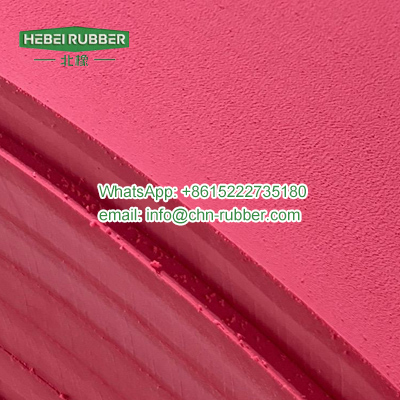

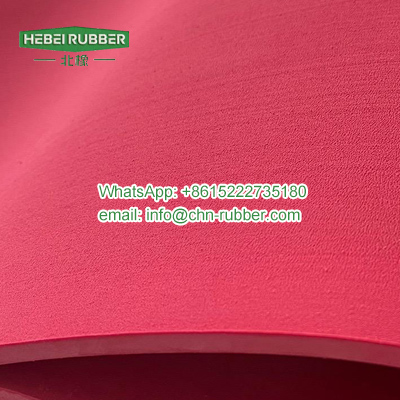

Rubber wear lining is a highly effective solution for protecting equipment and structures from excessive wear, impact, and corrosion in demanding industrial environments. Made from premium rubber compounds, these linings provide excellent resistance to abrasion, reducing maintenance costs and extending the lifespan of chutes, hoppers, tanks, and other critical components. Their flexibility allows for a snug fit on various surfaces, absorbing shocks and minimizing material buildup that can lead to operational inefficiencies.

Key Features:

Exceptional Abrasion Resistance – Protects against continuous friction, prolonging equipment life.

Impact Absorption – Reduces vibration and shock damage, minimizing wear on machinery.

Corrosion Protection – Acts as a barrier against chemicals, moisture, and harsh materials.

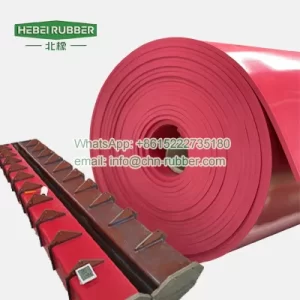

Versatile Application – Suitable for lining chutes, hoppers, cyclones, pipes, and material handling equipment.

Custom Fit – Available in sheets, panels, or molded shapes to accommodate different installation needs.

Applications:

Mining & Quarrying – Shields equipment from abrasive materials like ore, coal, and aggregates.

Cement & Steel Plants – Prevents premature wear in high-impact zones such as transfer points and bins.

Material Handling Systems – Enhances performance and reduces downtime in conveyors, silos, and feeders.

-137x56.png)

.jpg)