Wear resistant rubber performance

| PHYSICAL PROPERTY | TEST STANDARD | VALUES |

|---|---|---|

| Hardness | ASTM D2240 | 36+/-3Shore A |

| Specific Gravity | ASTM D397 | 0.96+/-0.03 |

| Modulus@500% | ASTM D412 | 2.1 |

| Tensile Strength | ASTM D412 | 23Min |

| Elongation | ASTM D412 | 800% |

| Resilience | / | 80% |

| Tear Strength | ASTM D624 | 40Min |

| Wet Abrasion | ASTM D5963 | 103% |

| Working Temperature | / | -40℃ ~ +80℃ |

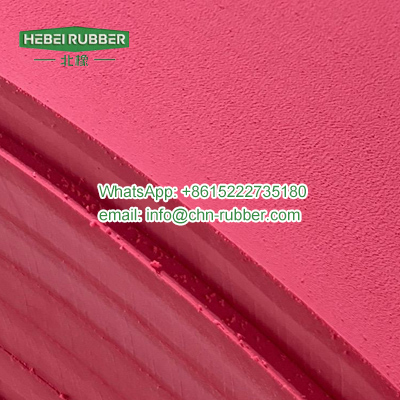

Wear-resistant skirtboard red gum rubber is a premium material known for its exceptional durability, flexibility, and abrasion resistance. Made from high-quality natural rubber, it provides superior cushioning and impact absorption, making it ideal for applications where material containment and equipment protection are critical. Wear resistant rubber high elasticity ensures a tight seal along conveyor belts, preventing spillage and reducing wear on machinery.

Key Features:

Outstanding Abrasion Resistance – Wear resistant rubber designed to withstand continuous friction and impact, extending the lifespan of conveyor systems.

Superior Flexibility – Adapts to movement and pressure changes, maintaining an effective seal without cracking or hardening.

High Tensile Strength – Resists tearing and deformation, even in demanding industrial conditions.

Shock Absorption – Skirtboard rubber provides excellent energy absorption, reducing vibrations and protecting equipment from excessive wear.

Easy Installation – Available in various thicknesses and widths to fit different conveyor belt systems and machinery.

Applications:

Conveyor Belt Skirting – Skirtboard rubber creates a tight seal to prevent material spillage and dust buildup.

Industrial Linings – Protects chutes, hoppers, and impact zones from wear and tear.

Belt Wipers and Seals – Ensures efficient material handling by maintaining belt cleanliness and stability.

With red gum rubber combination of strength, flexibility, and impact resistance, wear-resistant skirtboard red gum rubber is the go-to solution for industries requiring reliable protection against abrasion and material loss.

-137x56.png)

-300x300.jpg)